High Speed Chill Roll attachment type LCRHS-700 and LCRHS-900 For films down to 10 microns with a line speed up to 100 meter per minute. This stack comprises of a main large 400 mm diameter chill roll which faces the die, followed by two rolls of 200 mm diameter. The large diameter chill roll enables a rapid cooling of the film, assisted by a vacuum box to enable instant contact of the melt to the chill roll surface without entrapment of air. The entire rolling stack is mounted on an individual heavy duty rigid frame, separated from the down stream unit but with common rail system. The high speed chill roll unit is made for production of single as well as multilayer films with a line speed of up to 100 meter/minute. For LCRHS-700 the width of rolling stack is 700 mm and it is suitable for production of films and sheets with a width up to around 650 mm. which after edge trimming will have a width of around 550 mm. For LCHRS-900 the width of rolling stack is 900 mm and it is suitable for production of films and sheets with a width up to around 800 mm.

Product Category: Cast Film and Co-Ex

-

Cast Film Line Type LCR-300

Heavy duty chill roll attachments. The roll width for LCR-300-HD is 350 mm and can produce films or sheets with a width of up, to 300 mm. For the larger LCR-350-HD, the roll widths are 400 mm and the film or sheet width is here up to 350 mm. All 3 rolls in the rolling stack have a diameter of 145 mm and they are all cored with internal chamber for water cooling and heating. The rolls can also be connected to oil heating units for high temperature applications.

-

Cast Film with MDO Line

Vertical machine direction stretching unit MDO, our MDO unit is a standalone stretching unit that for your convenience can be placed either ‘in-line’ or ‘off-line’ to a cast film or blown film extrusion line. It will stretch both single and multi-layer films to a maximum stretching rate of 10 times (depending on material). The MDO unit has 3 different setups available. ‘In-line’ with a multi-layer cast film line, ‘In-line’ with a multi-layer blown film line, and ‘Off-line’ as a stand alone unit. The MDO unit is supplied complete with 4 hot oil roll tempering units and all rolls are independently driven by designated servo motors with speed controls on the LCD touch screen.

-

Co-Extrusion Cast Film 3 Layer Line LCR-350 HD

The roll width for LCR-300-HD is 350 mm and can produce films or sheets with a width of up, to 300 mm. For the larger LCR-350-HD, the roll widths are 400 mm and the film or sheet width is here up to 350 mm. All 3 rolls in the rolling stack have a diameter of 145 mm and they are all cored with internal chamber for water cooling and heating. The rolls can also be connected to oil heating units for high temperature applications. The rolls are made of high grade tool steel of same high quality as we use for our two-roll mills. They are hardened and precision ground after which they are equipped with a hard chrome layer which again is precision ground and polished to a mirror surface. The whole rolling stack assembly can be positioned either vertically or horizontally.

-

Co-Extrusion Ultra Micro Cast Film 3 Layer: Co-Ex LUMCR-50

For producing films down to 10 µm and thin sheets up to 300 µm. Comprehensively tested with LLDPE, LD & HDPE and PP. More resin types are being tested.

As with all our other Ultra Micro lines, this Co-Ex version was designed and built by our engineers on their spare time and given as a gift to our manager. The line features two units of our conical extruder which have the unique features to be able to use regular plastic pellet sizes. This is made possible by having an in feed section diameter of 18 mm which then gradually reduces to 8 mm at the screw tip. All three rolls of the chill roll stack have a diameter of 40 mm and are same as our larger versions equipped for water cooling and heating. The line includes a roll tempering unit with circulating water, connected to all three rolls giving a temperature regulation from ambient temperature to a maximum of around 90° C. The roll width for the LUMCR-50 is 100 mm and can produce films or sheets with a width after neck-in of around 40 to 45 mm with the standard 50 mm die and 60 to 65 mm with the optional 75 mm die. The thickness range is around 10 to 300 microns. The rolls are made of stainless steel of same high quality as we use for our larger versions and are precision ground and polished to a mirror surface.

-

Compact Cast Film Line LBCR-150

Compact chill roll film and sheet extrusion line comprised of our Laboratory bench top single screw extruder Type LBE20-30/P for general extrusion of PE, PP, PS, ABS etc. Non-vented type equipped screw and barrel in high-grade nitride steel, screw diameter 20 mm and L/D ratio of 30. One unit Chill roll sheet/film attachment with flat film die allowing for 100 mm wide opening and adjustable lips for film and sheet thickness from 0.3 to 2.0 mm. Sheet and film chill roll attachment for horizontal extruder die connection. With large 145 mm diameter chill roll and additional cooling and polishing rolls. All 3 rolls are equipped with rotary joints and cored inside for cooling/heating water, which enables efficient temperature control of roll surface.

-

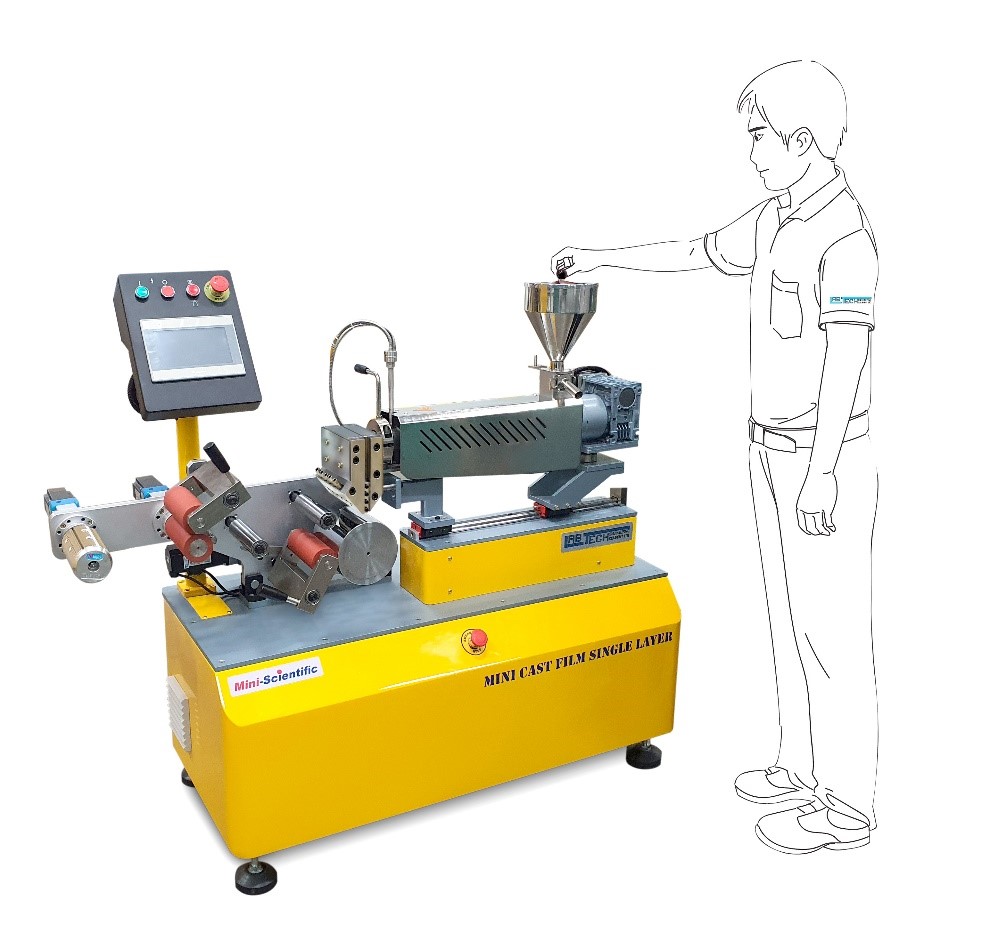

Mini Single-Layer Film and Sheet Line

Our New Scientific Mini Single-Layer Film and Sheet Line Type LMCR–150 is a viable low-cost alternative to our regular cast film lines. It has a mini-size extruder connected to a single-layer cast film die, and it is equipped with a vertically adjustable chill roll with a diameter of 145 mm and a width of 150 mm. This single-layer mini cast film can process PE, PP, PA6, PC, PET, EVOH, PLA, PS, ABS, and many other resin types.

THE LINE FEATURES:

- Mini design taking up a floor space of only 1.5 m x 0.7 m (5.0 x 2.3 ft) and a height of 1.2 m (4.0 ft) make it easy to fit into even the most crowded lab.

- The Mini Extruder can process regular polymer pellets

- The entire assembly is mounted on a sturdy steel subcabinet containing all major supply cables and electric components inside the subcabinet, giving a very clean appearance with very few visible connections to the extruder.

- The mini single-screw extruder is mounted on an elevated base on top of the subcabinet

- The die and the extruder are mounted individually on the same sliding rail, and the die can be separated from the extruder with a quick lock C-clamp. This enables easy removal of the extruder for cleaning and removing of the screw.

- The roll is vertically adjustable so that the gap between the die and the roll can be adjusted to reduce the necking of the extruded melt from the die.

- The rubber pressing roll of the chill roll has a handle that can be swung and securely locked into place away from or towards the roller. In the position where it presses against the chill roll, it serves to ensure that the film is tightly wrapped around the Chill Roll for optimum cooling efficiency. The pressure of this rubber pressing roll is adjustable with a spring-loaded screw

- The film tensioning nip is opened with a handle, and the nip force is adjustable with a spring-loaded screw

- The surface wind-up unit can hold a max film width of 125 mm, and it is equipped with an air expansion shaft holding a 3-inch bobbin

- The chill roll, haul-off nip-roll, and wind-up device are driven by three individual AC servo motors

- The line is equipped with a user-friendly 7-inch full central LCD touch screen unit controlling all functions like:

- extruder temperature and RPM

- die temperature

- chill roll temperature and RPM

- downstream nip-roll and wind-up RPM

-

Ultra Micro “Combi” Cast Film and Sheet line and Blown Film

We are pleased to present a unique combination unit of our Ultra Micro Cast film & sheet line type LUMCR-50 and Ultra Micro Blown film line type LUMF-150 supplied on same table top display and using same Ultra Micro Single screw extruder type LE8-30/C, as first presented at the K-show in Dusseldorf 2013. Both our Ultra Micro lines were secretly designed and built by our engineers and technicians during their spare time and were presented as a New Years gift to our company’s manager. A lot of engineering has gone into these machines which are completely designed and built from scratch and the result is truly amazing. In fact the Ultra Micro lines worked so well that we decided to also start offering them to our customer worldwide.

-

Ultra Micro Cast Film and Sheet Line: LUMCR-50

We are pleased to present the second addition to our Ultra Micro machine lines, the truly amazing fully functional cast film and sheet line built with same 8 mm extruder as we have for the Ultra Micro Blown Film line. A lot of engineering has gone into this machine which is completely designed and built from scratch and the result is truly amazing. What was even more amazing is that the line was not built as a model but instead as a professional functional line and with same high quality as our other machines so that it can be used for research and learning institutes for many years to come.