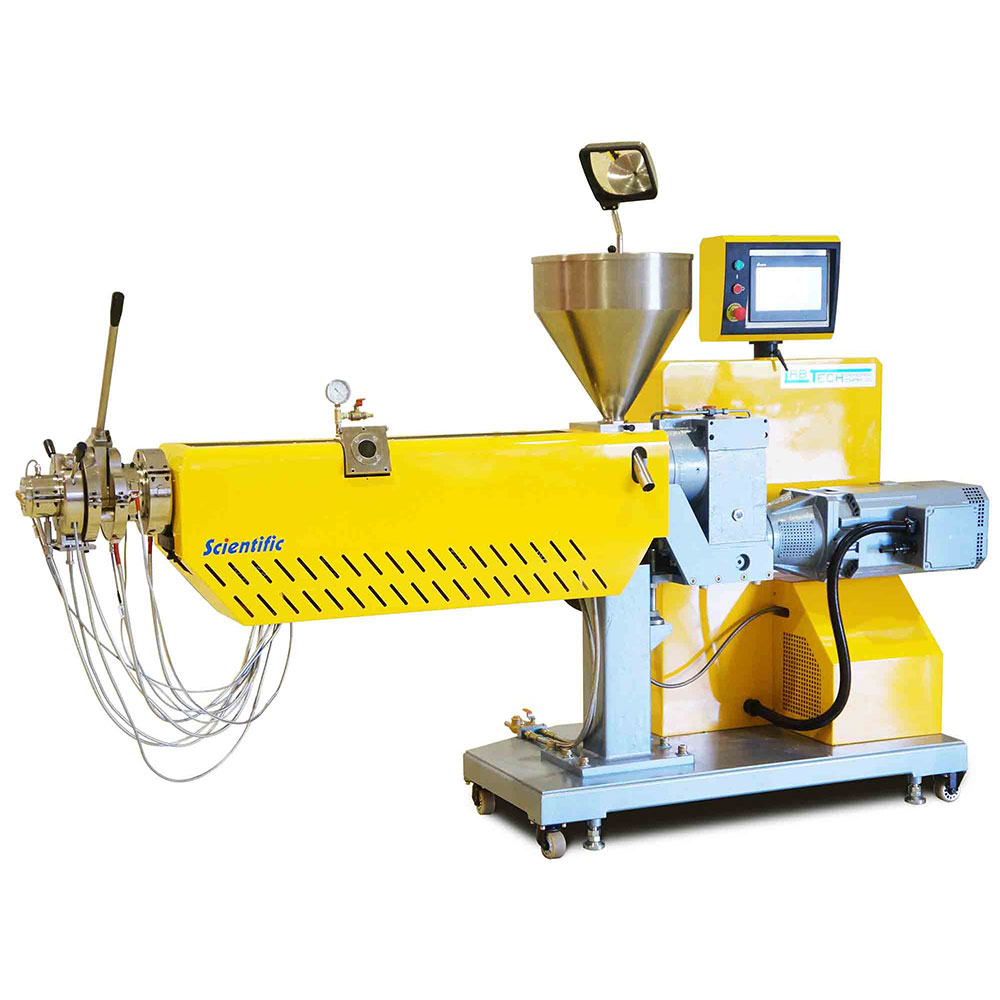

New amazing conical 12.5 mm single screw extruder that can be fed with regular pellets

This unique extruder was designed in house by our engineers and the actual screw design was made for us by Dr. Chris Rauwendaal, a world renowned expert on extrusion technologies. The purpose of the extruder is to be able to extrude minute amounts of resins and still be able to use regular resin pellet sizes. A straight 12.5 mm single screw extruder would have a much too small screw depth at the in feed section and then could only be fed with resins in powder forms.

This 12.5 mm conical single screw extruder can be used for compounding together with our small water bath type LWB40 and pelletizer LZ 80. But we think its main applications is with downstream single layers as well as co-extrusion multi layer film and sheet productions, where the very small output offers a very economic alternative against larger lines for research and educational purposes. Actually the first production of these small extruders was used for two sets of a 3-layers co-ex Chill Roll and Film Blowing lines. Here the conical design of the extruder screws proved to give an excellent plasticization and dispersion of the resin, equal to what is obtained with larger single screw extruders, even those equipped with mixing screws.